Etheredge Industrial Services

Check Out some of our Featured Projects!

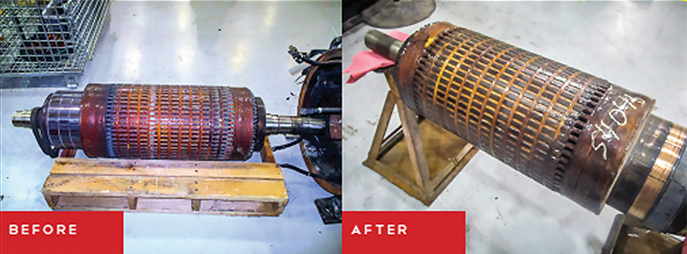

Paper Mill – 3000HP Synch Refiner Motor Repair-in-Place

During this Job, our highly trained Field Service Team:

-Removed the end segments of the Amortisseur Windings

-Re-welded the End Segments

-Cleaned the End Segments and all windings by Dry-Ice Blasting

-Set the Air Gap on the Exciter

-Connected the Diode Wheel

-Painted the inside with Red Varnish

-Reassembled the Motor

An extensive Repair Report with all testing and photo documentation was then provided to ensure the Quality of our workmanship. The Job was a great challenge but was executed right on schedule, and our Customer was very pleased with the results.

If you have ANY Repair or Motor-related problems or questions, don’t hesitate to reach out to us as we are always here to service your needs and keep your facility well maintained and fully operational.

Ultrasonic Cleaning Unit

We designed this unit to physically be capable of cleaning up to 2000 horsepower DC armatures. The inside dimensions are 10 1⁄2’ long by 4 1⁄2’ wide and 4 1⁄4’ deep. This Ultrasonic Unit is designed to remove trapped carbon/contamination in areas that are next to impossible to remove using other methods. Etheredge has been successful in extending the life of many armatures that would have otherwise been deemed a rewind.